Page 100 - ΝΑΥΤΙΚΑ ΧΡΟΝΙΚΑ - ΜΑΙΟΣ 2023

P. 100

GREEN SHIPPING

involves cooling the flue gas to focusing on CO₂ absorption by utilizing

extremely low temperatures, typ- chemicals to trap the CO₂ , then releas-

ically below -78 degrees Celsius, ing it storing it in liquid or solid form.

where CO₂ can be condensed and Carbon capture could be anything from

separated. The process relies on 30 % to 100 % in order to meet the

the different boiling points of CO₂ statutory requirements of keeping the

and other gases in the flue gas CO₂ trading costs low. One MT of fuel

mixture. By cooling and pressuriz- will be generating more than 3.2 MT of

ing the flue gas, CO₂ can be cap- CO₂ excluding the additional fuel that

tured and subsequently released will have to be consumed during the

by reducing the pressure. Cryo- carbon capture and storage process.

genic separation is energy-in- Apart from the use of amines, one of

tensive but has the advantage of the most promising technologies is CO₂

producing a relatively high-purity absorption using Ammonium hydroxide.

CO₂ stream. In this process, the flue gas contain-

Carbon capture technology onboard ing CO₂ is passed through an absorber

ships is a developing field; more than column where it comes into contact

30 companies (many of them spon- with a stream of NH₄OH solution. The

sored by Green funds available from CO₂ reacts with NH₄OH to form ammo-

their national governments) are now nium bicarbonate (NH₄HCO₃), which is

trying to develop and test onboard then separated from the solution. The

CCS systems that will enable to cap- solution is then regenerated by heating

ture and store CO₂ at economically it, which releases the CO₂ and water

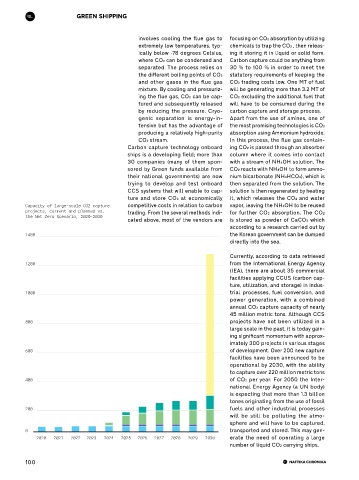

Capacity of large-scale CO2 capture competitive costs in relation to carbon vapor, leaving the NH₄OH to be reused

projects, current and planned vs. trading. From the several methods indi- for further CO₂ absorption. The CO₂

the Net Zero Scenario, 2020-2030

cated above, most of the vendors are is stored as powder of CaCO₃ which

according to a research carried out by

1400 the Korean government can be dumped

directly into the sea.

Currently, according to data retrieved

1200 from the International Energy Agency

(IEA), there are about 35 commercial

facilities applying CCUS (carbon cap-

ture, utilization, and storage) in indus-

1000 trial processes, fuel conversion, and

power generation, with a combined

annual CO₂ capture capacity of nearly

45 million metric tons. Although CCS

800 projects have not been utilized in a

large scale in the past, it is today gain-

ing significant momentum with approx-

imately 300 projects in various stages

600 of development. Over 200 new capture

facilities have been announced to be

operational by 2030, with the ability

to capture over 220 million metric tons

400 of CO₂ per year. For 2050 the Inter-

national Energy Agency (a UN body)

is expecting that more than 1.3 billion

tones originating from the use of fossil

200 fuels and other industrial processes

will be still be polluting the atmo-

sphere and will have to be captured,

0 transported and stored. This may gen-

2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 erate the need of operating a large

number of liquid CO₂ carrying ships.

100