SKF SPEEDI-SLEEVE restores worn shafts quickly & economically

Over time, contaminants and conditions can cause particles to become trapped inside a lip seal. Particles then form wear grooves on the shaft, eventually leading to seal failure and severe shaft damage. Repairs are expensive, time-consuming and too often, ineffective. With an SKF SPEEDI-SLEEVE, they are also unnecessary.

SKF SPEEDI-SLEEVE can be installed without having to disassemble the shaft or specify a new replacement seal size, and offers an excellent sealing surface.

Go from scored shaft to restored shaft in minutes

SKF SPEEDI-SLEEVE is a very thin-walled shaft repair sleeve that provides a quicker, more cost-effective alternative to dismantling and re-machining a worn shaft. An SKF SPEEDI-SLEEVE mounts quickly and easily without power tools or heating.

SPEEDI-SLEEVE_2

Often capable of delivering a better quality counterface for the seal lip than the original shaft, SKF

SPEEDI-SLEEVE also:

Eliminates expense of replacing or reworking shafts

Requires no shaft disassembly or machining

Enables same size replacement seal as original

Provides an excellent, wear-resistant sealing surface

Can be easily installed with no power tools or heating

A new seal counterface in a few minutes

Although installation is simple, it should be done carefully to achieve the best results. As the thin-walled sleeve has an interference fit, any disturbances on the shaft surface may create a similar pattern on the sleeve surface and cause the seal to leak. Therefore, the seal counterface surface of the shaft should be carefully cleaned and any burrs or rough spots filed down prior to installation. Deep wear grooves, scratches or very rough surfaces should be treated with a suitable powdered metal epoxy-type filler. The sleeve must be positioned on the shaft before the filler has hardened.

SKF SPEEDI-SLEEVE must not be installed over keyways, cross holes, splines or threads since this will result in deformation of the sleeve, making it difficult for the seal to follow its new counterface surface as it rotates.

SKF SPEEDI-SLEEVE should never be heated prior to installation. Using heat will cause the sleeve to expand, but when it cools, it may not contract back to its original size, resulting in a loose fit on the shaft.

ΝΧ

Συντακτική ομάδα Ναυτικών Χρονικών

Στην Diana Shipping το 7,72% της Genco

To 7,72% των μετοχών της Genco Shipping & Trading απέκτησε η Diana Shipping σύμφωνα με filing της πρώτης στην αμερικανική επιτροπή κεφαλαιαγοράς. Η εταιρεία…

Πράσινο φως της ΕΕ για το 18ο πακέτο κυρώσεων κατά της Ρωσίας

Την τελική έγκριση του 18ου πακέτου κυρώσεων κατά της Ρωσίας έδωσε το Συμβούλιο Γενικών Υποθέσεων σήμερα στις Βρυξέλλες. Το 18ο πακέτο κυρώσεων περιλαμβάνει νέα…

Μπρα ντε φερ ΗΠΑ-Ν. Κορέας για τεράστιες επενδύσεις στην αμερικανική αγορά

Έντονη είναι η ανησυχία στους κλάδους της παραγωγικής βιομηχανίας της Νότιας Κορέας. Σύμφωνα με ΜΜΕ από την ασιατική χώρα, οι ΗΠΑ απαίτησαν από τη…

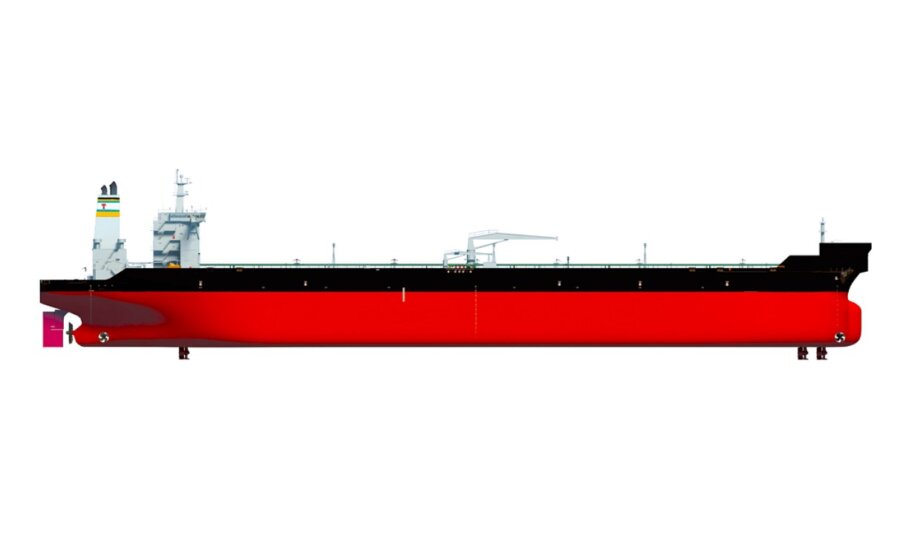

H νορβηγική τεχνογνωσία, ούριος άνεμος στα πανιά των νέων shuttle tankers του Ομίλου Τσάκου

Τα εννέα νέα shuttle tankers του Ομίλου Τσάκου θα ενσωματώσουν προηγμένα συστήματα ναυτικής τεχνολογίας της Kongsberg Maritime. Συγκεκριμένα, η Kongsberg Maritime επελέγη από τη…

Το πρώτο πλοίο ανεφοδιασμού αμμωνίας

Η παγκόσμια μετάβαση σε καύσιμα μηδενικών εκπομπών βρίσκει στην αμμωνία έναν υποσχόμενο σύμμαχο. Η ναυτιλιακή τεχνολογία εισέρχεται πλέον σε μια εποχή, με την κατασκευή…

Τεχνολογική αναβάθμιση του στόλου της Hyundai Glovis με την πλατφόρμα της Avikus

Με τεχνολογικό επίκεντρο το προηγμένο σύστημα HiNAS Control της Avikus, η Hyundai Glovis προχωρά στην πρώτη εκτεταμένη εφαρμογή αυτόνομης ναυσιπλοΐας στον στόλο των πλοίων…

Απογείωση της επιβατικής κίνησης στα ελληνικά αεροδρόμια

Άνοδο 5,2% καταγράφει η επιβατική κίνηση, για το α΄ εξάμηνο του 2025, στο σύνολο των αεροδρομίων της χώρας, σε σχέση με το αντίστοιχο χρονικό…

Εκ νέου σκόπελοι για την ενεργειακή ασφάλεια της Αιγύπτου

Νέους σκοπέλους συναντά η Αίγυπτος στο μέτωπο της ενεργειακής ασφάλειας, καθώς ένας σημαντικός αριθμός φορτίων LNG που αναμένονταν τον Ιούλιο επαναπρογραμματίζονται για τον Αύγουστο.…