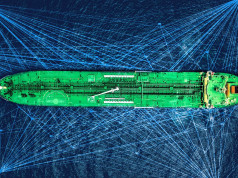

Remote control of cranes improves productivity and working ergonomics in new Maasvlakte 2 container terminals; will be first in Europe to operate without a driver on board

ABB, the leading power and automation technology group, recently won contracts from two major container terminal operators, APM Terminals and Rotterdam World Gateway (RWG) to provide automation systems for their new ship-to-shore cranes. ABB’s delivery will enable the cranes to be operated remotely, without a driver on board, for improved overall efficiency.

The two new terminals that will open in 2014 in Rotterdam at Maasvlakte 2 will be the first in Europe to use remote control of ship-to-shore (STS) cranes, and the terminal of APM Terminals will be the first in the world where STS cranes have no driver’s cabin installed.

“These projects underscore the need for fast and cost-effective container handling, and how the latest automation technologies can be applied to dramatically increase efficiency as a response to higher productivity requirements,” said Veli-Matti Reinikkala, head of ABB’s Process Automation division.

The remote control of cranes improves overall productivity and working ergonomics for crane operators. The new terminals of APM Terminals and RWG in Rotterdam are designed to serve the largest container ships, which require lifting heights of over 50 meters. ABB’s system for remote control of STS cranes has the crane operators working in a control room located in the terminal building, where they supervise the cranes. This will improve working ergonomics and help reduce the stress on operator’s back and neck.

Operators supervise the crane motion via onboard cameras; often the camera views are more comprehensive than the views available from inside the crane cabin. Combined with access to control information provided by the automation system, these help to improve overall operator performance.

With a crane operator on board, crane acceleration and deceleration rates are limited. With no operator on board, the crane can run faster and ramp times can be shorter. This enables significantly shorter cycle times to unload an entire ship’s worth of cargo.

ABB’s system automates the crane’s corrective movements to ensure accuracy and speed. With no operator on board, more aggressive corrections can be made, which further reduces cycle times and contributes to higher productivity.

Over the years, ABB has delivered automation and electrification for almost 400 stacking cranes and nearly 600 STS cranes. With the recently awarded projects ABB’s remote control technology for STS cranes has made a breakthrough on the market. The first remotely controlled STS crane has been in commercial operation since December 2010 in Panama, where ABB worked in close cooperation with Manzanillo International Terminal (MIT) to develop the remote control technology for STS cranes.

ABB (www.abb.com) is a leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 145,000 people.